1. Maklumat Keselamatan

Always prioritize safety when operating the FLARING Plasma Cutter. Failure to follow safety guidelines can result in serious injury or property damage.

- Alat Pelindung Diri (PPE): Always wear appropriate PPE, including a welding helmet with a suitable shade, flame-resistant clothing, heavy-duty gloves, and safety shoes.

- Pengudaraan: Ensure adequate ventilation in the work area to disperse fumes and gases produced during cutting. Avoid working in confined spaces.

- Bahaya Kebakaran: Keep flammable materials away from the cutting area. Have a fire extinguisher readily available. Sparks and molten metal can travel significant distances.

- Keselamatan Elektrik: Connect the machine to a properly grounded power supply. Do not operate in wet conditions. Inspect cables and connections for damage before each use.

- Udara termampat: Use clean, dry, oil-free compressed air. Ensure air pressure is within the recommended range.

- Permukaan Panas: The torch and workpiece will become extremely hot during operation. Allow them to cool before handling.

2. Produk Lebihview

The FLARING FC650D is a versatile and portable 65 Amp plasma cutter designed for efficient and clean cutting of various metal types. It features advanced IGBT inverter technology and dual voltage capability for flexible power options.

The FLARING FC650D Plasma Cutter and its included accessories.

Illustration of key features including large capacitance, dual voltage, strong heat dissipation, fast cutting, and ease of use.

Ciri-ciri Utama:

- High Efficiency Cutting: Max severance cut up to 4/5" (20 mm), ideal clean cut 1/2" (12.7mm) with 60% duty cycle.

- Dwi Voltage: Operates on both 120V and 240V (50/60 Hz) power sources without manual relinking.

- Aplikasi luas: Suitable for cutting aluminum, magnesium alloys, brass, stainless steel, cast iron, steel, copper, titanium, and other metal materials.

- Mudah Alih dan Ringan: Weighs only 8.4 pounds, making it easy to transport.

- Stabil dan Tahan Lama: Features automatic arc control for consistent cutting, reducing user fatigue.

The plasma cutter utilizes an Original IGBT chip for reliable performance.

An efficient cooling fan ensures strong heat dissipation during operation.

3. Components and Panel Introduction

Your FLARING FC650D Plasma Cutter comes with the following components:

- FC650D Plasma Cutter Unit

- PT31 Torch (9.9ft)

- Heavy-duty ground clamp dengan kabel

- Air regulator and hose

- 7 Elektrod

- 7 Petua

- Hos Gas

- Conversion line 120V to 240V

A visual representation of the upgraded FC650D accessories included with your plasma cutter.

Panel Pengenalan:

Terperinci view of the plasma cutter's control panel and connections.

- Paparan Digital LED

- Current Adjustable Knob

- Penyambung Obor

- Suis Obor

- Bumi Clamp Penyambung

- Suis Kuasa

- Kabel Kuasa

- Tombol Kawalan Tekanan

- Kipas Penyejuk

- Tolok Tekanan

4. Persediaan

- Sambungan Kuasa: Connect the power cable to a suitable 120V or 240V (50/60 Hz) power outlet. The machine automatically detects the voltage. Use the provided conversion line if necessary.

- Sambungan Bekalan Udara: Connect your compressed air source to the air regulator. Attach the air hose from the regulator to the plasma cutter's air inlet. Ensure the air supply is clean, dry, and oil-free. Set the air pressure using the Pressure Control Knob and monitor with the Pressure Gauge.

- Sambungan Obor: Connect the PT31 Torch to the Torch Connector on the front panel. Ensure it is securely fastened.

- Tanah Clamp Sambungan: Attach the heavy-duty ground clamp to the Earth Clamp Connector. Securely clamp tanah clamp to the workpiece or a clean, bare metal part of the work table, ensuring good electrical contact.

- Consumables Check: Verify that the torch tip and electrode are correctly installed and in good condition. Replace if worn.

5. Arahan Operasi

Follow these steps for effective and safe plasma cutting:

- Hidupkan kuasa: Flip the Power Switch to the 'ON' position. The LED Digital Display will illuminate.

- Laraskan Arus: Use the Current Adjustable Knob to set the desired cutting current (Amps) based on the material type and thickness. Refer to the specifications table for recommended settings.

- Laraskan Tekanan Udara: Ensure the air pressure is set correctly for optimal cutting performance. The recommended range is typically indicated on the machine or in the specifications.

- Sediakan Bahan Kerja: Ensure the workpiece is clean and free of rust, paint, or other contaminants that could interfere with the arc.

- Mulakan Arka: Position the torch nozzle close to the edge of the workpiece. Press the Torch Switch to initiate the pilot arc.

- Mula Memotong: Once the pilot arc is established, move the torch steadily across the material. Maintain a consistent travel speed and standoff distance for a clean cut. The machine's automatic arc control helps maintain the arc, even over expanded metal.

- Cutting Various Materials: The FC650D is capable of cutting a wide range of metals, including steel, stainless steel, aluminum, copper, brass, and cast iron. Adjust current and speed accordingly.

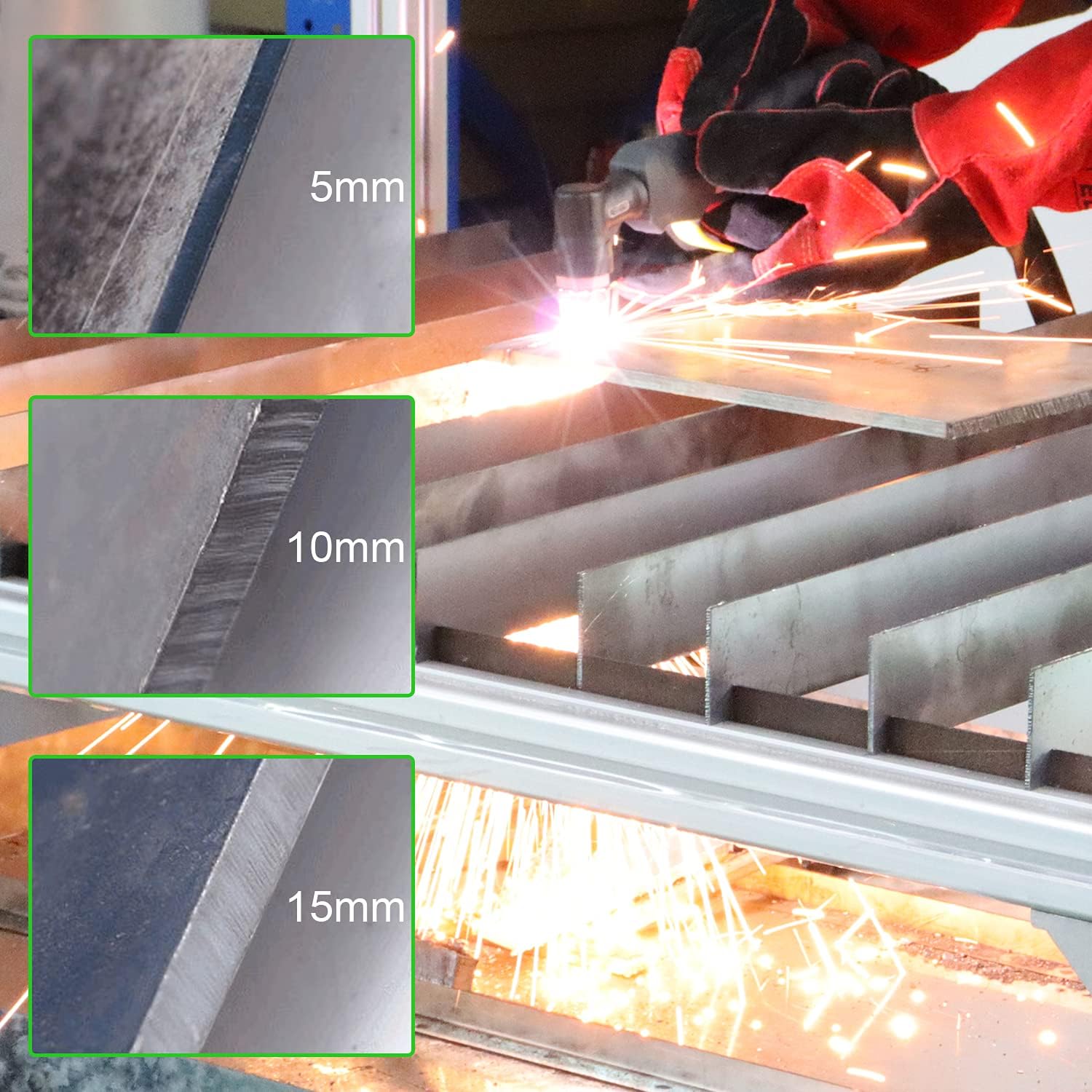

Examples of plasma cutting on different metal thicknesses (5mm, 10mm, 15mm).

The plasma cutter is suitable for a wide range of applications, including various metals and alloys.

Video Demonstrasi:

This video demonstrates the FLARING Touch Arc Plasma Cutter in action, specifically cutting aluminum sheet metal. It showcases the machine's capability and the cutting process.

6. Penyelenggaraan

Penyelenggaraan tetap memastikan jangka hayat dan prestasi optimum pemotong plasma anda.

- Consumable Replacement: Regularly inspect and replace worn torch tips and electrodes. Worn consumables can lead to poor cut quality and damage to the torch.

- Air Filter/Regulator: Periodically check and drain any moisture from the air filter/regulator. Ensure the filter element is clean to prevent contaminants from entering the torch.

- Pembersihan: Pastikan mesin bersih dan bebas daripada habuk dan zarah logam. Gunakan udara termampat untuk meniup keluar komponen dalaman jika perlu, pastikan mesin dicabut daripada plag.

- Pemeriksaan Kabel: Periksa semua kabel (kuasa, obor, tanah) untuk mengesan pemotongan, melecet atau sambungan yang longgar. Membaiki atau menggantikan kabel yang rosak dengan segera.

7. Penyelesaian masalah

If you encounter issues with your plasma cutter, refer to the following common problems and solutions:

| Masalah | Kemungkinan Punca | Penyelesaian |

|---|---|---|

| Tiada Arka / Arka Gagal Bermula | No power, poor ground connection, worn consumables, insufficient air pressure. | Periksa bekalan kuasa, pastikan pembumian terjagaamp is secure on bare metal, replace tip/electrode, verify air pressure. |

| Poor Cut Quality / Rough Cut | Worn consumables, incorrect cutting speed, incorrect current setting, improper standoff distance, contaminated air. | Replace consumables, adjust travel speed, adjust current, maintain correct torch distance, check air filter/dryer. |

| Mesin Terlalu Panas | Exceeding duty cycle, blocked cooling vents, high ambient temperature. | Allow machine to cool down, ensure proper ventilation around the unit, operate within duty cycle limits. |

| Kebocoran Udara | Loose air hose connections, damaged O-rings. | Ketatkan sambungan, periksa dan gantikan O-ring jika rosak. |

If problems persist after attempting these solutions, please contact FLARING customer support.

8. Spesifikasi

Detailed technical specifications for the FLARING FC650D Plasma Cutter:

Official specification chart for the FC650D model.

| Atribut | Nilai |

|---|---|

| Pengeluar | MENJALANKAN |

| Nombor Bahagian | FC650D |

| Berat Barang | 15.17 paun |

| Dimensi Pakej | 16 x 12.75 x 10.75 inci |

| Nombor Model Item | FC650D |

| Corak | FC650D-65A-Touch ARC |

| Sumber Kuasa | AC |

| Voltage | 120/240 Volt |

| Kuantiti Pakej Item | 1 |

| Komponen yang Disertakan | 7 electrodes, 7 tips, Air regulator and hose, FC650D PLASMA CUTTER, Heavy-duty ground clamp with cable, PT31 Torch |

| Bateri Termasuk? | Tidak |

| Bateri Diperlukan? | Tidak |

| Tarikh Mula-mula Tersedia | 25 April 2024 |

9. Waranti dan Sokongan

For information regarding product warranty, technical support, or service, please refer to the documentation provided with your purchase or contact FLARING customer service directly. You can often find contact details on the manufacturer's official webtapak atau melalui tempat pembelian anda.