1. Produk Lebihview

This manual provides essential information for the installation, operation, and maintenance of the Starter Motor, part numbers 103-5287 dan 1109458. This starter motor is designed for specific Caterpillar CAT Engine 4M40 Excavator models.

Ciri-ciri Utama:

- Direct replacement for part numbers 103-5287 and 1109458.

- Compatible with Caterpillar CAT Engine 4M40.

- Suitable for Excavator models 307, 306, and 307B.

2. Maklumat Keselamatan

Always observe safety precautions when working with automotive electrical systems and heavy machinery. Failure to do so may result in serious injury or damage to equipment.

- Disconnect the battery's negative terminal before beginning any work on the electrical system.

- Pakai peralatan pelindung diri (PPE) yang sesuai, termasuk cermin mata keselamatan dan sarung tangan.

- Ensure the vehicle or equipment is stable and properly supported before working underneath it.

- Elakkan sentuhan dengan komponen enjin yang panas.

- Rujuk juruteknik bertauliah jika anda tidak pasti tentang sebarang langkah pemasangan.

3. Panduan Pemasangan

This section outlines the general steps for replacing a starter motor. Specific procedures may vary depending on the exact model of Caterpillar excavator. Refer to your excavator's service manual for detailed instructions.

3.1 Alat Diperlukan

- Set perengkuh soket

- Set sepana hujung terbuka

- Battery terminal cleaner

- Berus wayar

- Sepana tork (disyorkan)

3.2 Removal of Old Starter Motor

- Sediakan Kenderaan: Ensure the excavator is turned off, the parking brake is engaged, and the battery's negative terminal is disconnected.

- Locate the Starter Motor: Identify the starter motor, typically mounted on the engine block near the flywheel.

- Putuskan Sambungan Pendawaian: Carefully disconnect the main battery cable and the solenoid wire(s) from the starter motor. Note their positions for reinstallation.

- Keluarkan Bolt Pemasangan: Loosen and remove the mounting bolts that secure the starter motor to the engine block. Support the starter motor as bolts are removed to prevent it from falling.

- Buang Starter Lama: Carefully maneuver and remove the old starter motor from its mounting position.

3.3 Installation of New Starter Motor

- Periksa Permukaan Pemasangan: Clean the mounting surface on the engine block to ensure a proper fit.

- Jawatan Pemula Baharu: Carefully align the new starter motor with the mounting holes on the engine block.

- Install Mounting Bolts: Insert and hand-tighten the mounting bolts. Once all bolts are in place, tighten them to the manufacturer's specified torque (refer to excavator service manual).

- Sambungan Pendawaian: Reconnect the main battery cable and solenoid wire(s) to the appropriate terminals on the new starter motor. Ensure connections are clean and secure.

- Sambung semula Bateri: Reconnect the battery's negative terminal.

- Operasi Ujian: Attempt to start the engine to verify proper operation of the new starter motor. Listen for unusual noises and ensure the engine cranks smoothly.

4. Visual Produk

Rajah 4.1: Depan view of the starter motor, highlighting the solenoid and main electrical terminals. The 24V marking is visible on the solenoid.

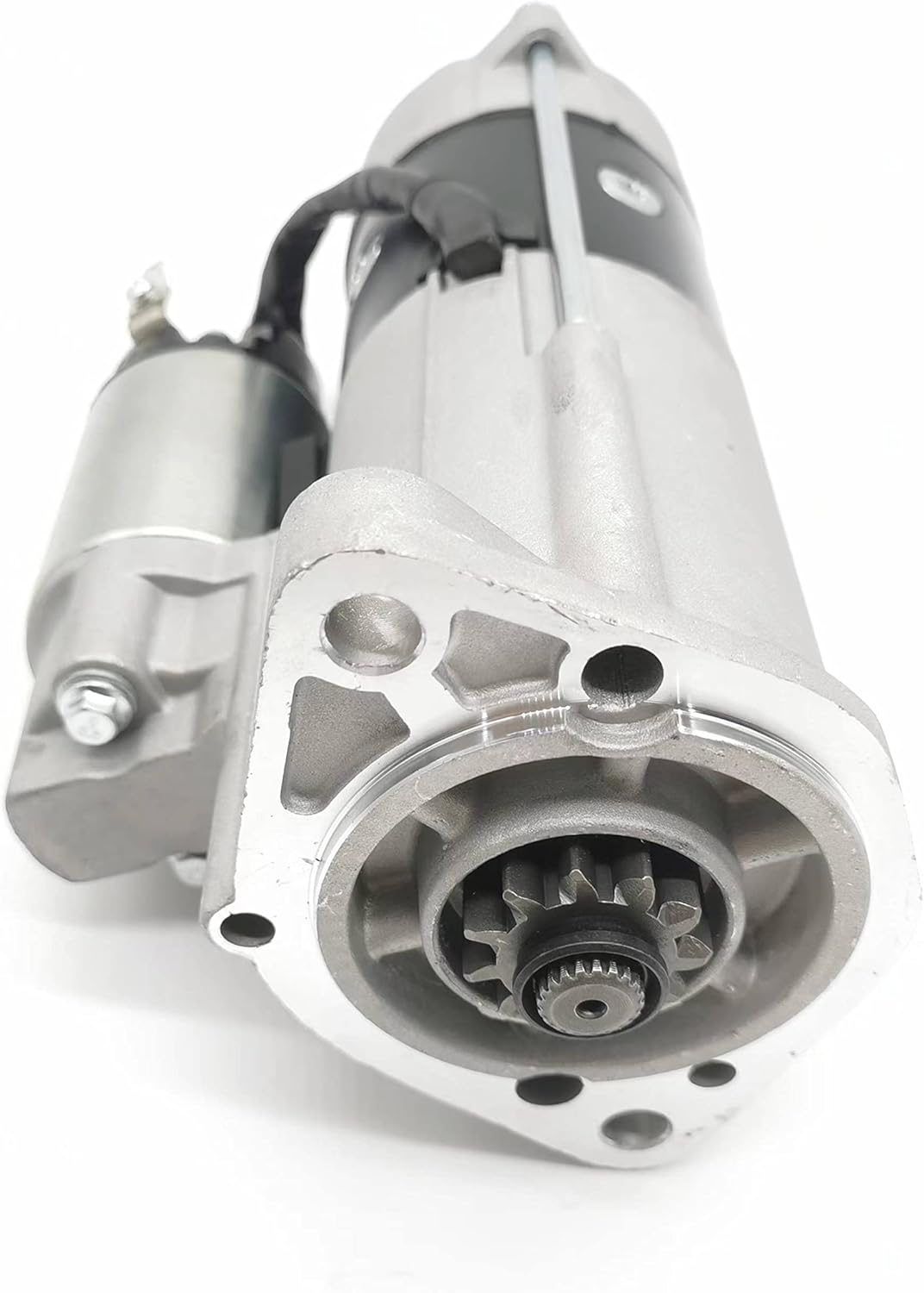

Rajah 4.2: View of the starter motor's drive end, showing the pinion gear and the mounting flange with bolt holes. This part engages with the engine's flywheel.

Rajah 4.3: Pro sampinganfile of the starter motor, illustrating its overall length and the relative positioning of the main body and solenoid.

Rajah 4.4: Top-down perspective of the starter motor, providing a clear view of the motor casing and the solenoid assembly.

Rajah 4.5: bersudut view of the starter motor, emphasizing the mounting points and the drive gear end.

Rajah 4.6: belakang view of the starter motor, showing the back end of the motor casing and the 24V label on the solenoid.

Rajah 4.7: Terperinci view of the electrical connection terminals on the solenoid, including the main battery post and the smaller control wire terminal.

Rajah 4.8: Satu lagi bersudut view focusing on the drive gear (pinion) and the mounting flange, providing a different perspective of the engagement mechanism.

5. Penyelenggaraan

Starter motors are generally low-maintenance components. However, periodic checks can extend their lifespan and ensure reliable operation.

- Sambungan Elektrik: Periodically inspect all electrical connections to the starter motor for corrosion or looseness. Clean terminals with a wire brush and battery terminal cleaner if necessary.

- Bolt Pemasangan: Check that the starter motor mounting bolts remain tight. Vibration can cause them to loosen over time.

- Keadaan Bateri: Ensure the vehicle's battery is in good condition and fully charged. A weak battery can put excessive strain on the starter motor.

6. Penyelesaian masalah

| simptom | Kemungkinan Punca | Penyelesaian |

|---|---|---|

| Enjin tidak engkol atau engkol perlahan. | Weak or dead battery; Loose or corroded battery cables; Faulty starter solenoid; Faulty starter motor. | Check battery charge and terminals; Clean and tighten battery cables; Test starter solenoid; Test or replace starter motor. |

| Starter motor clicks but engine does not crank. | Bateri rendah voltage; Faulty starter solenoid; Loose electrical connections. | Charge or replace battery; Check and tighten all electrical connections; Test or replace starter solenoid. |

| Grinding noise during cranking. | Damaged starter pinion gear or flywheel teeth; Misalignment of starter motor. | Inspect pinion gear and flywheel; Re-align or replace starter motor if necessary. |

7. Spesifikasi

- Nombor Bahagian: 103-5287, 1109458

- Permohonan: Caterpillar CAT Engine 4M40 Excavator 307, 306, 307B

- Jenama: NC

- Bahan: logam

- Voltage: 24V (as indicated on product images)

8. Waranti dan Sokongan

For warranty information or technical support, please contact your point of purchase or the manufacturer directly. Keep your purchase receipt as proof of purchase.

Manufacturer: N\C