1. Pengenalan

This manual provides essential information for the safe and efficient operation, installation, and maintenance of your U.S. Solid Solenoid Valve. Please read this manual thoroughly before installation and use, and keep it for future reference.

A solenoid valve is an electromechanical device that controls the flow of liquid or gas using an electromagnetic coil. This valve consists of a solenoid coil, a plunger (movable iron core), and a valve body with inlet and outlet ports. When current flows through the coil, a magnetic field is generated, attracting the plunger and operating to open or close the valve. This action allows or blocks the flow of liquid or gas depending on the design and function.

U.S. Solid solenoid valves are widely used in various industries such as industrial automation, HVAC systems, water management, medical equipment, and automotive systems. They are an indispensable component in situations requiring precise control, high-speed response, and reliable operation.

2. Maklumat Keselamatan

- Always disconnect power before installing, servicing, or cleaning the valve.

- Ensure the valve is compatible with the media (liquid or gas) and operating conditions (pressure, temperature) of your system.

- Jangan melebihi vol yang ditentukantage or pressure ratings.

- Install the valve in a location that allows for proper ventilation and access for maintenance.

- Ensure all connections are secure and leak-free before applying pressure or power.

- This solenoid valve has an IP65 protection rating, allowing it to be used outdoors or in humid environments, but it cannot be used underwater. If permanently installed outdoors, we recommend placing it under a roof or inside a protective box to prevent prolonged exposure to rain.

3. Produk Lebihview dan Ciri

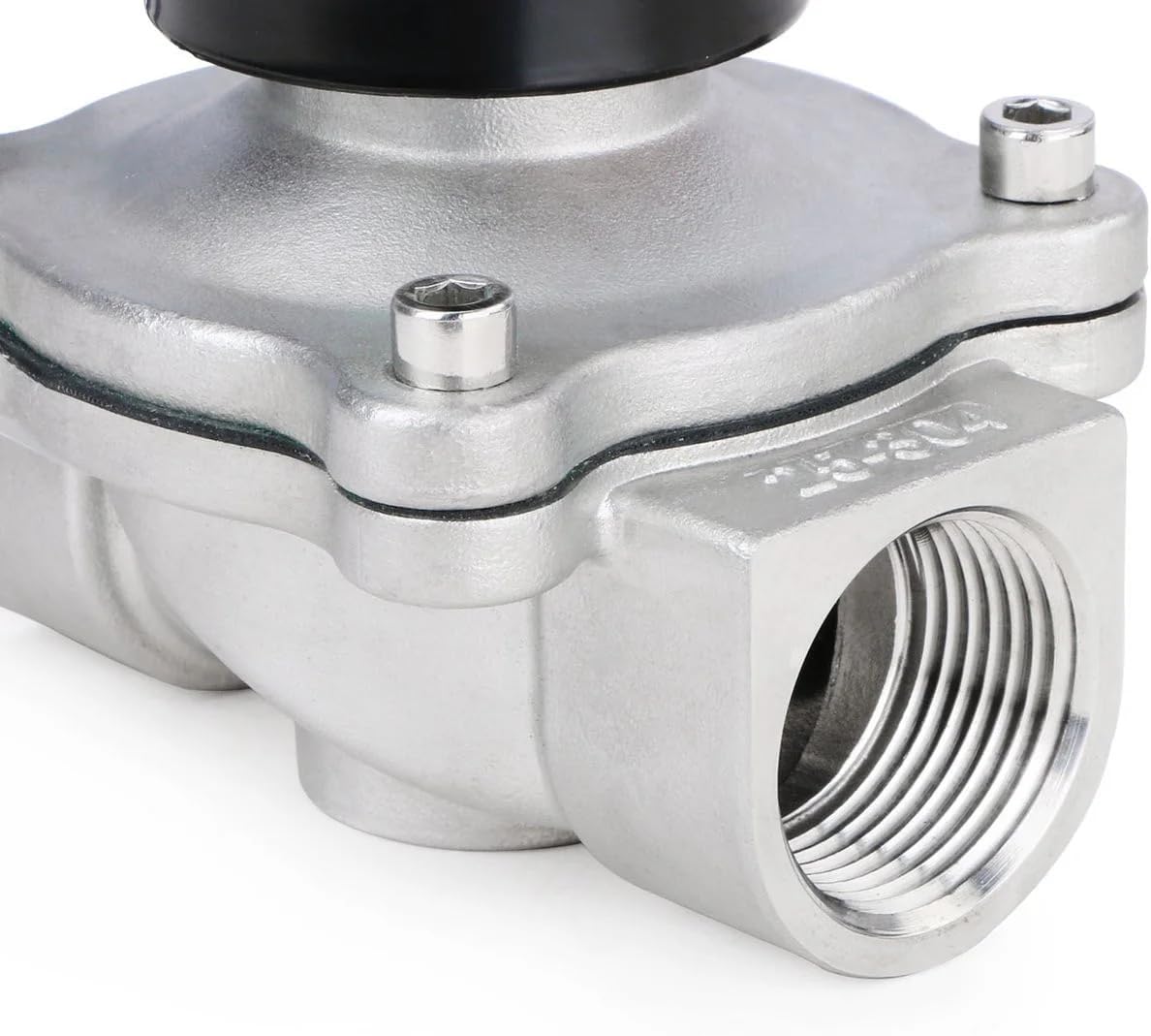

Produk utama view of the U.S. Solid Solenoid Valve.

Depan view showing the inlet/outlet port.

belakang view displaying the electrical wiring connection.

Pro sampinganfile of the solenoid valve.

Terperinci view of the 1-inch G-type internal threaded port.

Close-up of the port, showing the flow direction arrow.

Ciri-ciri Utama:

- Pembinaan Berkualiti Tinggi: The valve body is made of high-quality 304 stainless steel, suitable for various media, including potable water.

- Sambungan Standard: Features standard G-type internal threads (1 inch thread size, 25mm nominal diameter) for easy integration into existing systems.

- Pengedap Tahan Lama: Equipped with high-performance VITON seals, offering excellent high-temperature resistance, chemical corrosion resistance, and oil resistance, making it suitable for harsh environments.

- Respon Pantas: Allows for high-speed opening and closing control in milliseconds. This is a normally closed type valve, opening immediately after power is applied.

- Perlindungan Alam Sekitar: IP65 protection rating for outdoor and humid environment use (not submersible).

4. Spesifikasi

| Spesifikasi | Perincian |

|---|---|

| Jenama | US Solid |

| Nombor Model Produk | USS2-00070 |

| Dimensi Produk (LxWxH) | 9.9 x 7.6 x 12.7 cm |

| Berat Barang | 1.15 Kilogram |

| warna | Keluli Tahan Karat |

| bahan | Keluli Tahan Karat |

| Komponen yang Disertakan | Injap Solenoid |

| Bateri Termasuk | Tidak |

| Jenis Injap | Injap Solenoid |

| Saiz Sambungan Masuk | 1 inci |

| Jenis Sambungan Masuk | BSPP (G-type internal thread) |

| Saiz Sambungan Outlet | 1 inci |

| Jenis Sambungan Outlet | BSPP (G-type internal thread) |

| Bilangan Pelabuhan | 2 |

| Kemasan Luaran | Keluli Tahan Karat |

| Penilaian Perlindungan | IP65 |

5. Persediaan dan Pemasangan

5.1. Pemeriksaan Pra-Pemasangan

- Verify that the valve's voltage (AC 110V) and thread size (1 inch G-type) match your system requirements.

- Ensure the media passing through the solenoid valve is filtered to prevent impurities from entering the valve.

- Inspect the valve for any visible damage before installation.

5.2. Pemasangan Paip

- Identify the inlet and outlet ports. The valve typically has an arrow indicating the flow direction.

- Apply appropriate thread sealant (e.g., PTFE tape) to the male threads of your piping.

- Carefully thread the valve onto the pipes, ensuring a tight, leak-free connection. Do not overtighten.

- Ensure the valve is installed in the correct orientation for media flow.

Rajah 1: Close-up of the valve body, highlighting the threaded connection point.

Rajah 2: Illustrates the application of thread sealant to ensure a secure connection.

5.3. Sambungan elektrik

- Ensure the power supply is off before making electrical connections.

- Connect the valve's wires to the AC 110V power supply according to local electrical codes.

- Secure all electrical connections to prevent accidental disconnection or short circuits.

6. Arahan Operasi

This U.S. Solid Solenoid Valve is a biasanya ditutup type. This means that when no power is applied, the valve remains closed, blocking the flow of media. When electrical power (AC 110V) is applied to the solenoid coil, the valve opens, allowing media to flow through.

Nota Operasi Penting:

- The valve opens immediately after power is applied, providing quick response for various applications.

- Do not use this solenoid valve continuously for more than 8 hours. Prolonged continuous use can cause the internal electromagnetic coil to overheat and damage, shortening the solenoid valve's lifespan or causing malfunctions.

- For applications requiring the valve to remain open or closed for extended periods (beyond 8 hours), it is recommended to use products from our electric ball valve series, which are designed for continuous duty.

Thermal image illustrating heat generation during operation, emphasizing the need to adhere to usage limits.

7. Penyelenggaraan

Regular maintenance ensures the longevity and optimal performance of your solenoid valve.

7.1. Pembersihan

- If the medium contains many impurities, prolonged use may cause impurities to accumulate inside the valve body, degrading sealing performance and potentially leading to leakage.

- To resolve this, disconnect power and pressure, then carefully disassemble the valve body.

- Clean any accumulated impurities from the internal components, especially the plunger and seal areas.

- Reassemble the valve, ensuring all seals are correctly seated and connections are secure.

7.2. Penjagaan Am

- Periodically check for any signs of leakage around the connections or valve body.

- Ensure the electrical connections remain secure and free from corrosion.

- With normal operation and proper maintenance, this solenoid valve can provide long-lasting service.

8. Penyelesaian masalah

Isu dan Penyelesaian Biasa:

- Injap tidak terbuka/tertutup:

- Check power supply: Ensure AC 110V is correctly applied to the coil.

- Check for obstructions: Impurities in the media can prevent the plunger from moving freely. Refer to the cleaning instructions in the Maintenance section.

- Coil damage: If the coil overheated due to prolonged continuous use, it might be damaged. Replace the coil or valve if necessary.

- Kebocoran:

- Loose connections: Tighten pipe connections, ensuring proper thread sealant was used during installation.

- Damaged or dirty seals: Impurities can degrade sealing performance. Disassemble and clean the valve, or replace the VITON seals if they are worn or damaged.

- Overheating of coil:

- Exceeding continuous operation limit: Ensure the valve is not operated continuously for more than 8 hours. Allow for cool-down periods.

- vol. salahtage: Verify the power supply voltage matches the valve's rating (AC 110V).

9. Waranti dan Sokongan

U.S. Solid products are manufactured to high-quality standards. For specific warranty information, please refer to the product packaging or contact U.S. Solid customer support directly.

For technical assistance, troubleshooting, or replacement parts, please visit the official U.S. Solid website or contact their customer service department. When contacting support, please have your product model number (USS2-00070) and purchase information ready.